Vision

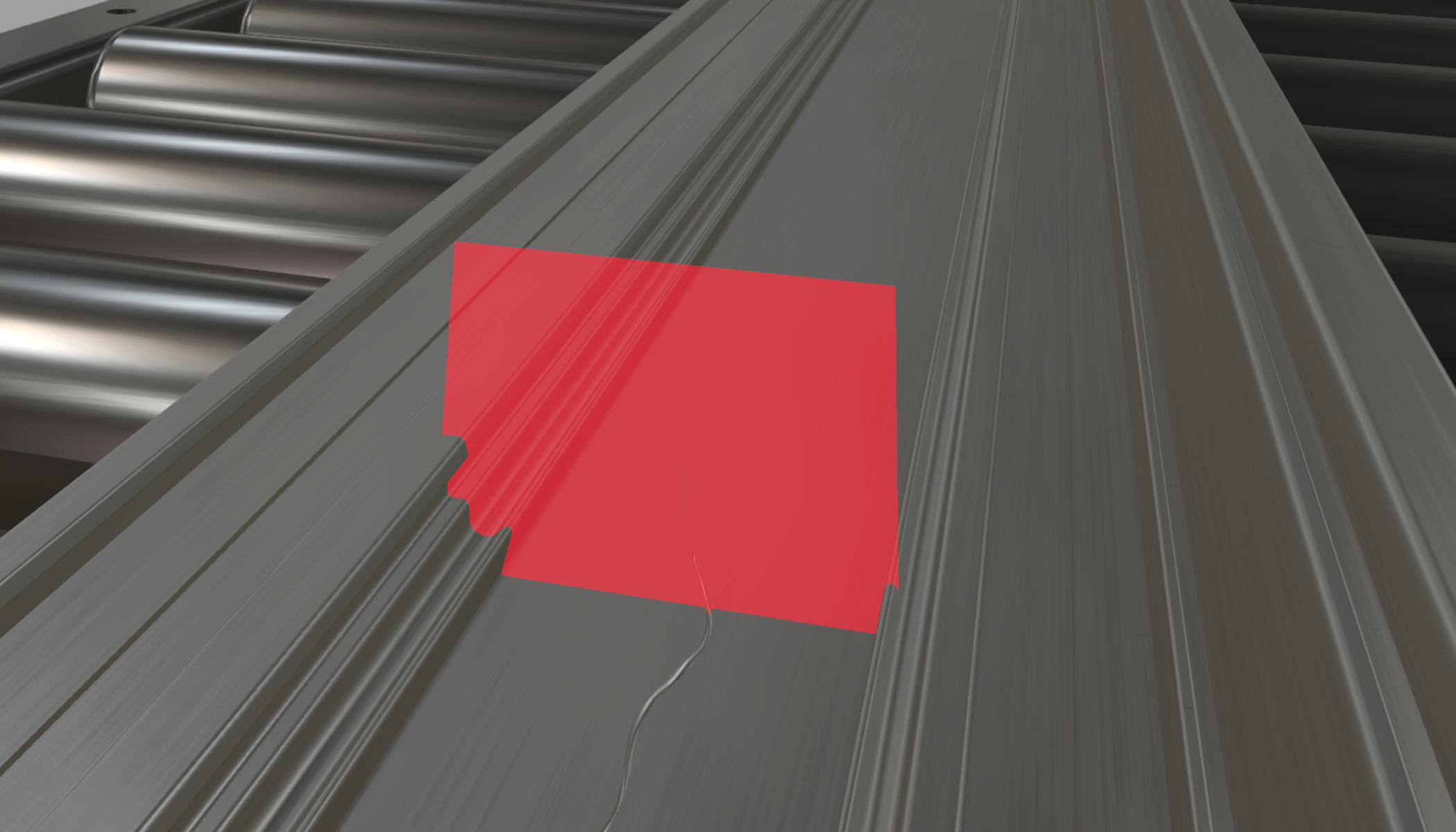

Defect / anomaly detection

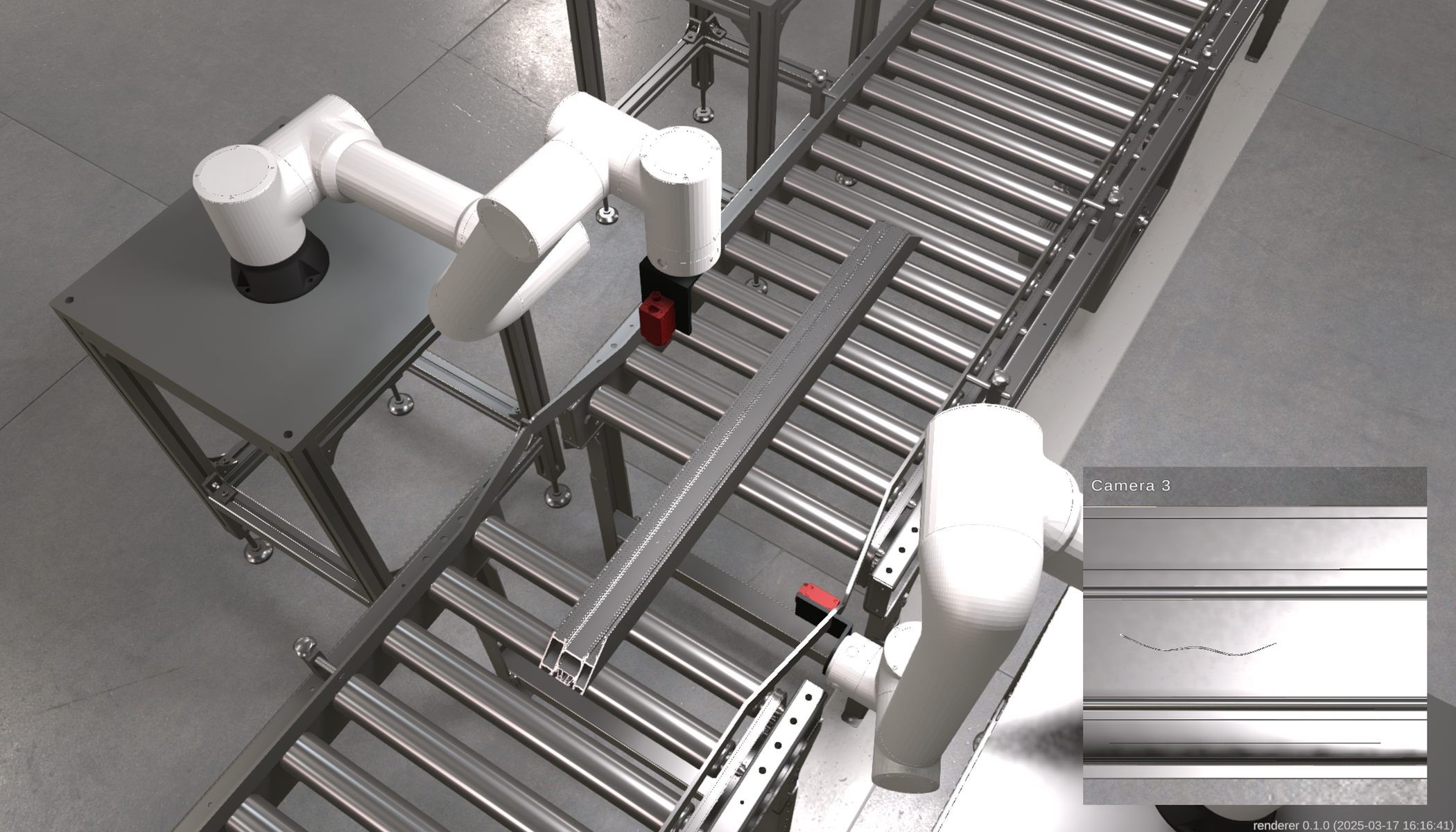

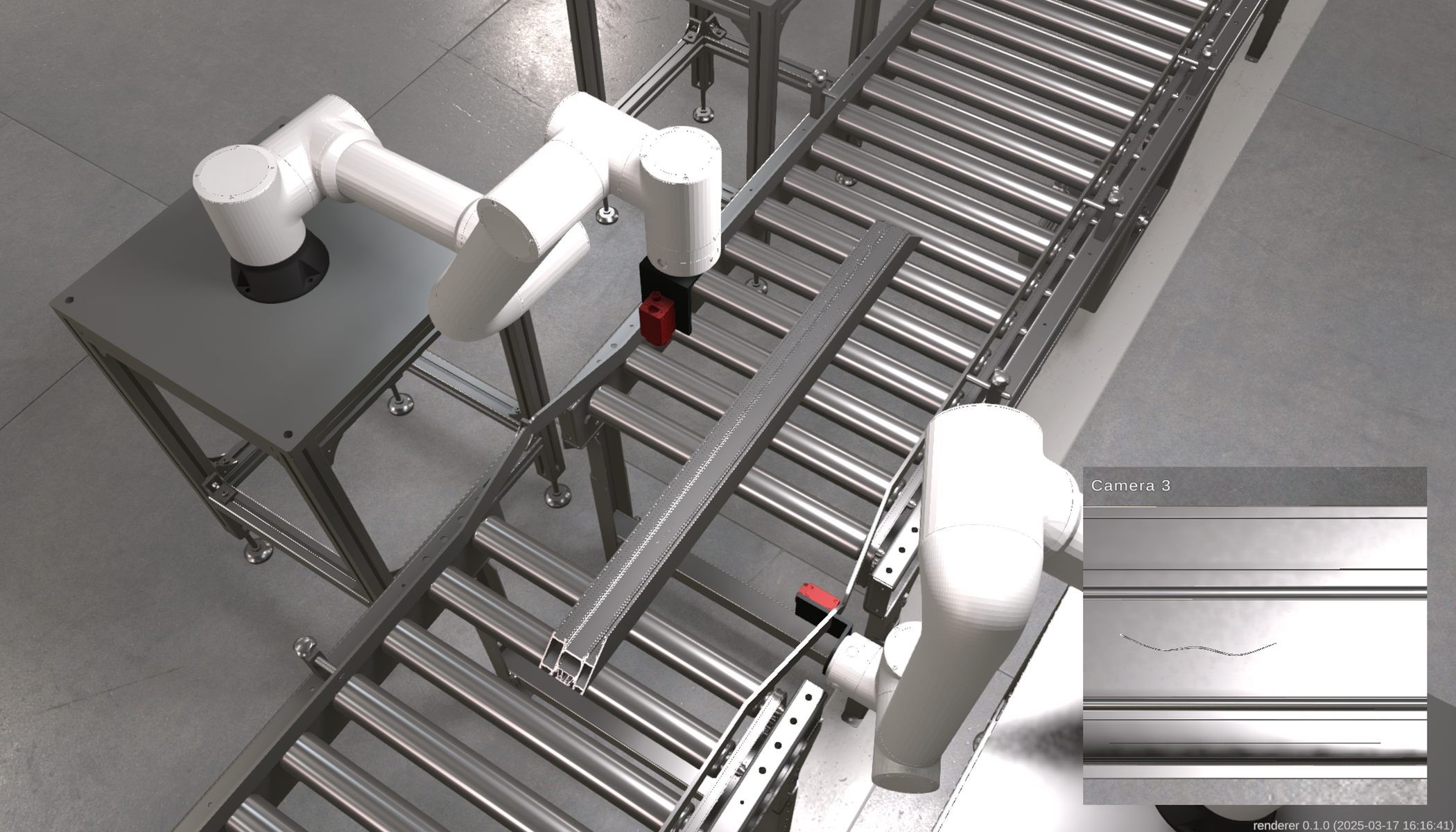

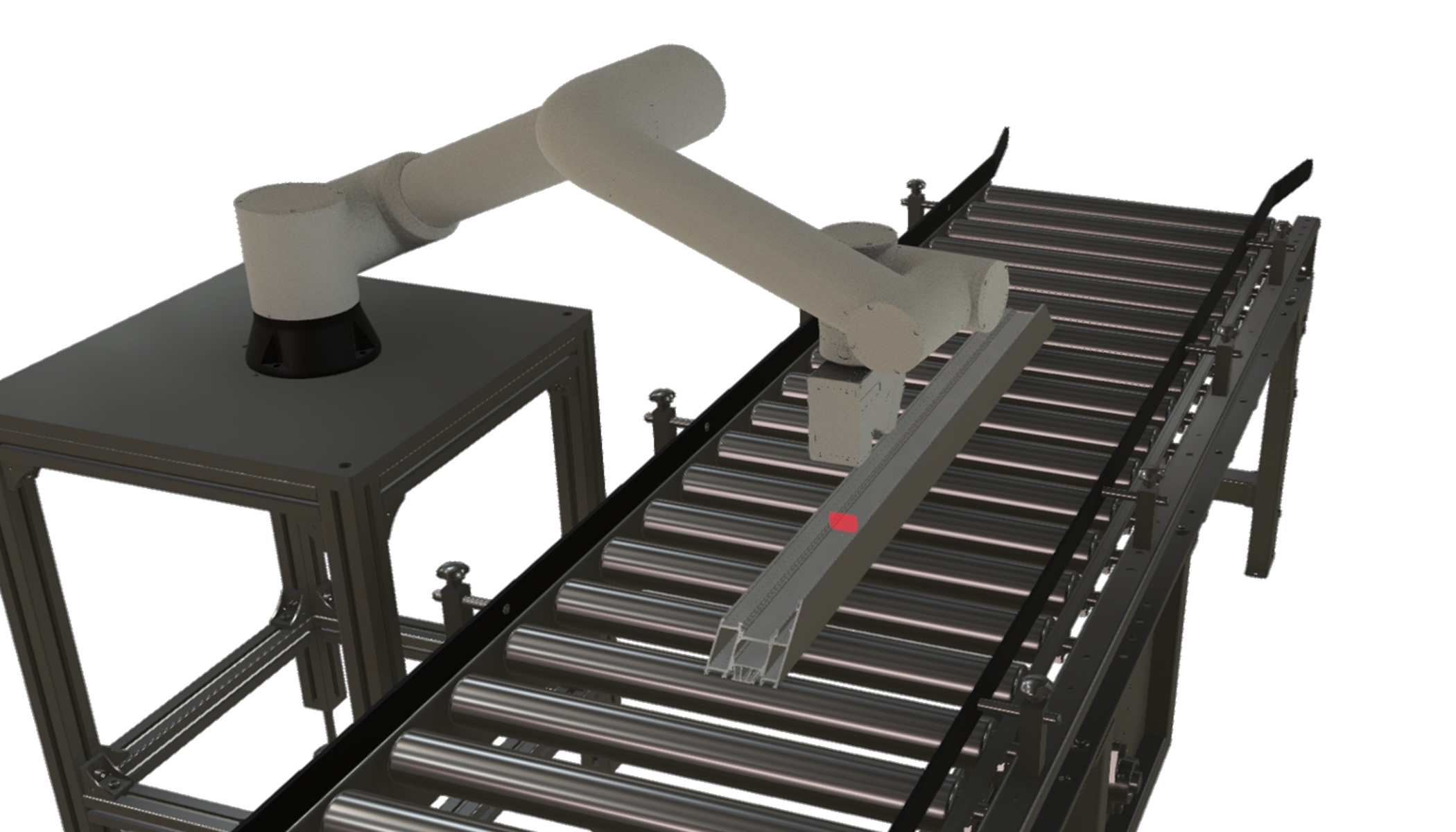

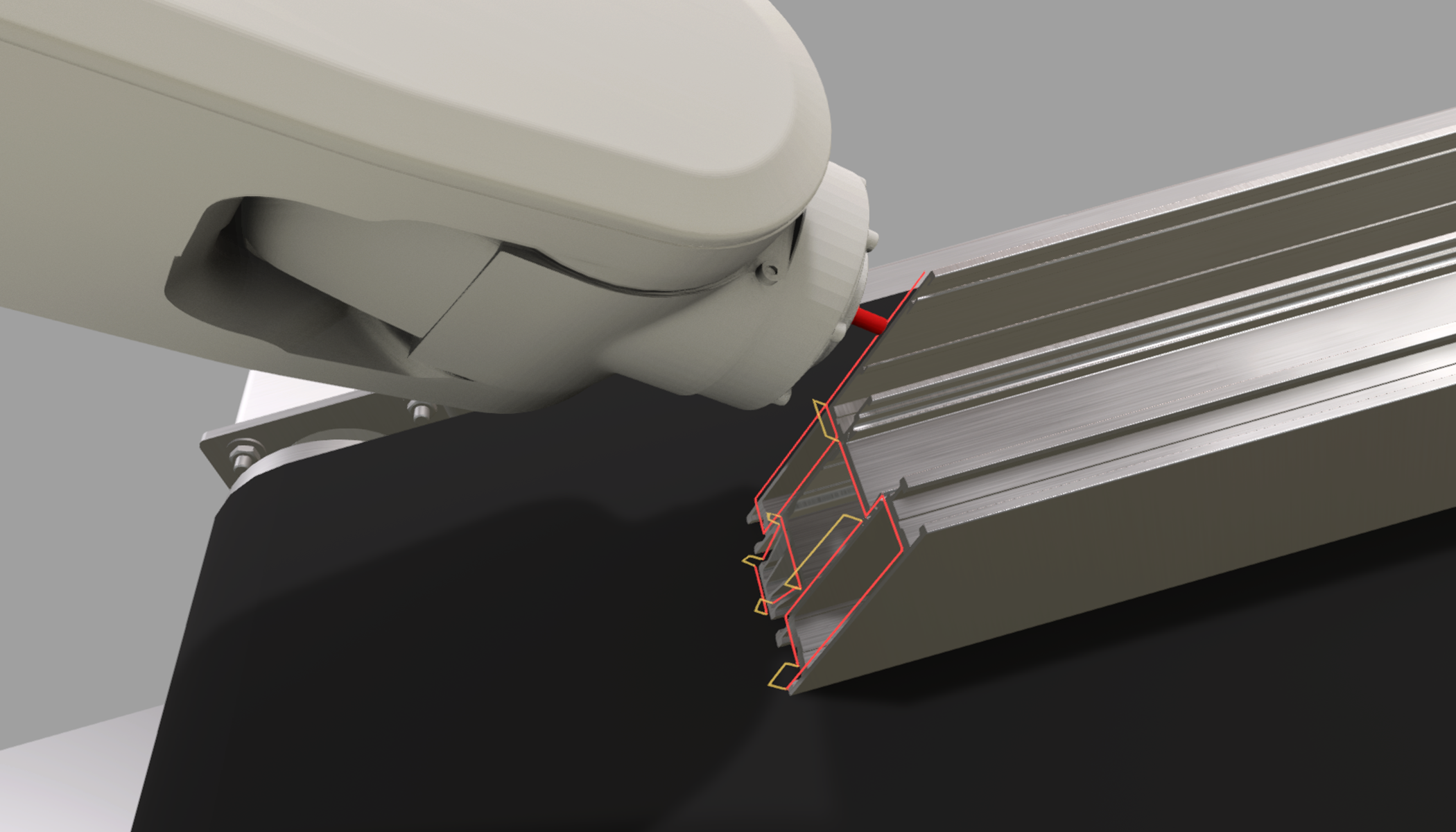

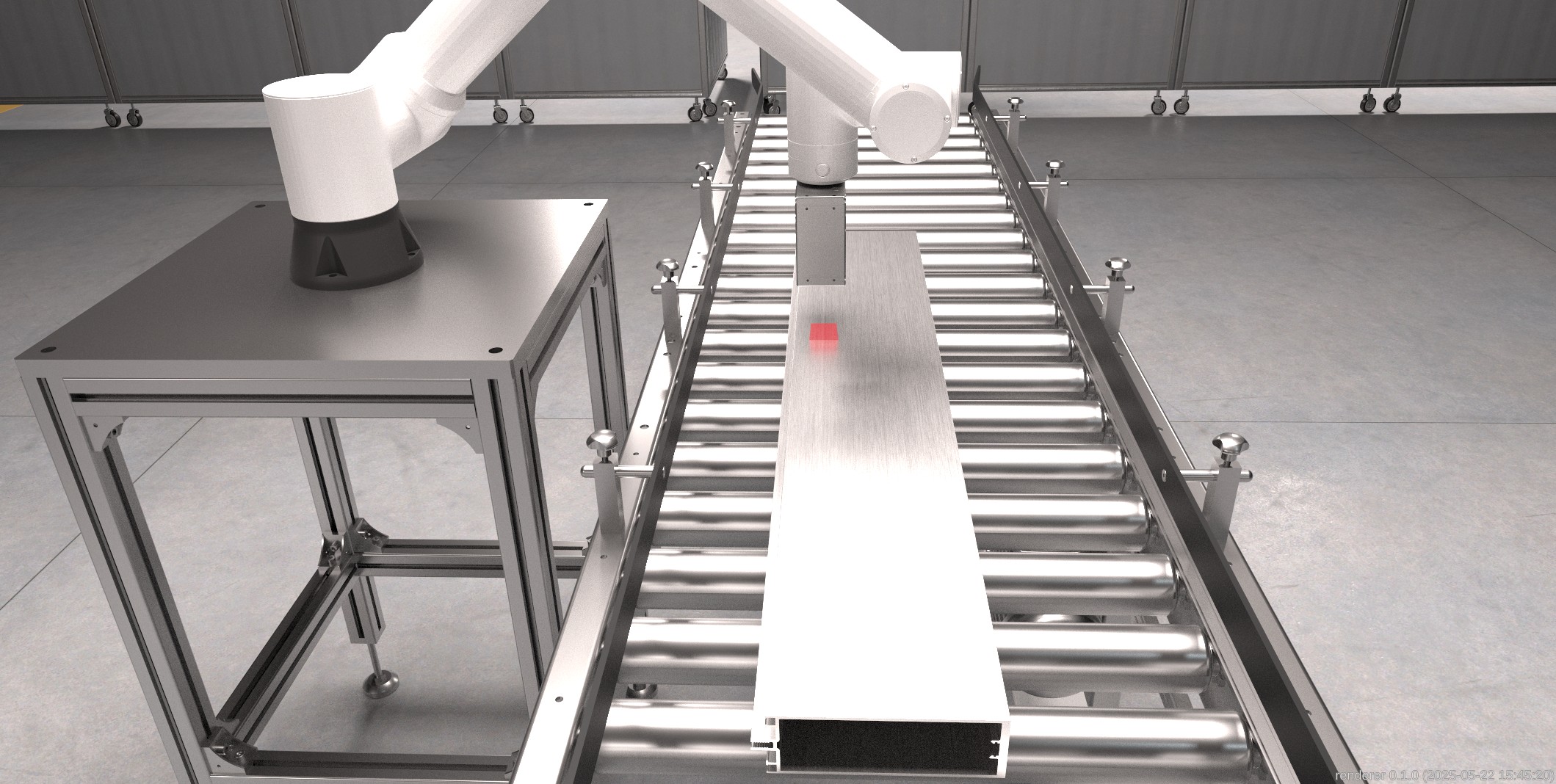

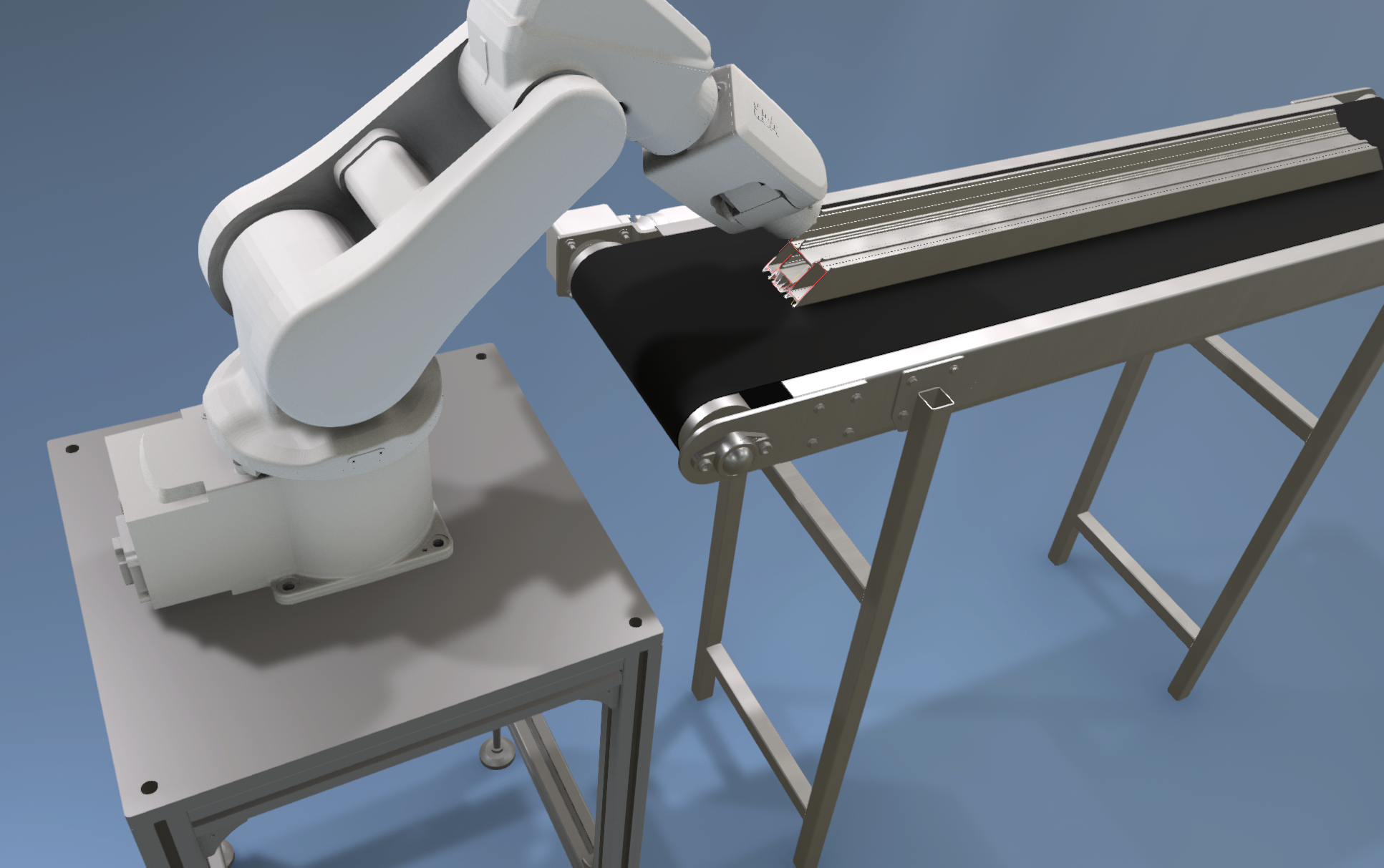

SIMULATION

Synigen builds a full digital twin of your production cell for vision, robotics, and laser scanning. Simulate optics, lighting, sensors, and robot paths to test inspection algorithms before hardware exists.

Defect / anomaly detection

2D / 3D laser scan simulation

Robotics simulation

Create a configurable digital twin and simulate object detection, recognition, and robotic movements — without needing deep expertise in software, AI, or ML. Validate optics, materials, and sensor choices early.

Simulate 2D and 3D laser scanning to detect surface variations and plan vision-guided workflows. Iterate parameters, sensor placement, and motion profiles without stopping production.

Simulate welding, gluing, or guided trajectories with real-time visualization. Define, test, and refine robot paths without writing code — reduce programming time and catch issues early.