HARDWARE

Curf delivers turnkey vision systems: e.g. CSI-100, an inline anomaly detector for painted or blank extruded profiles; and LPS, a line-scan inspection setup for blank aluminium that catches form errors and, most importantly, pressure lines at speed.

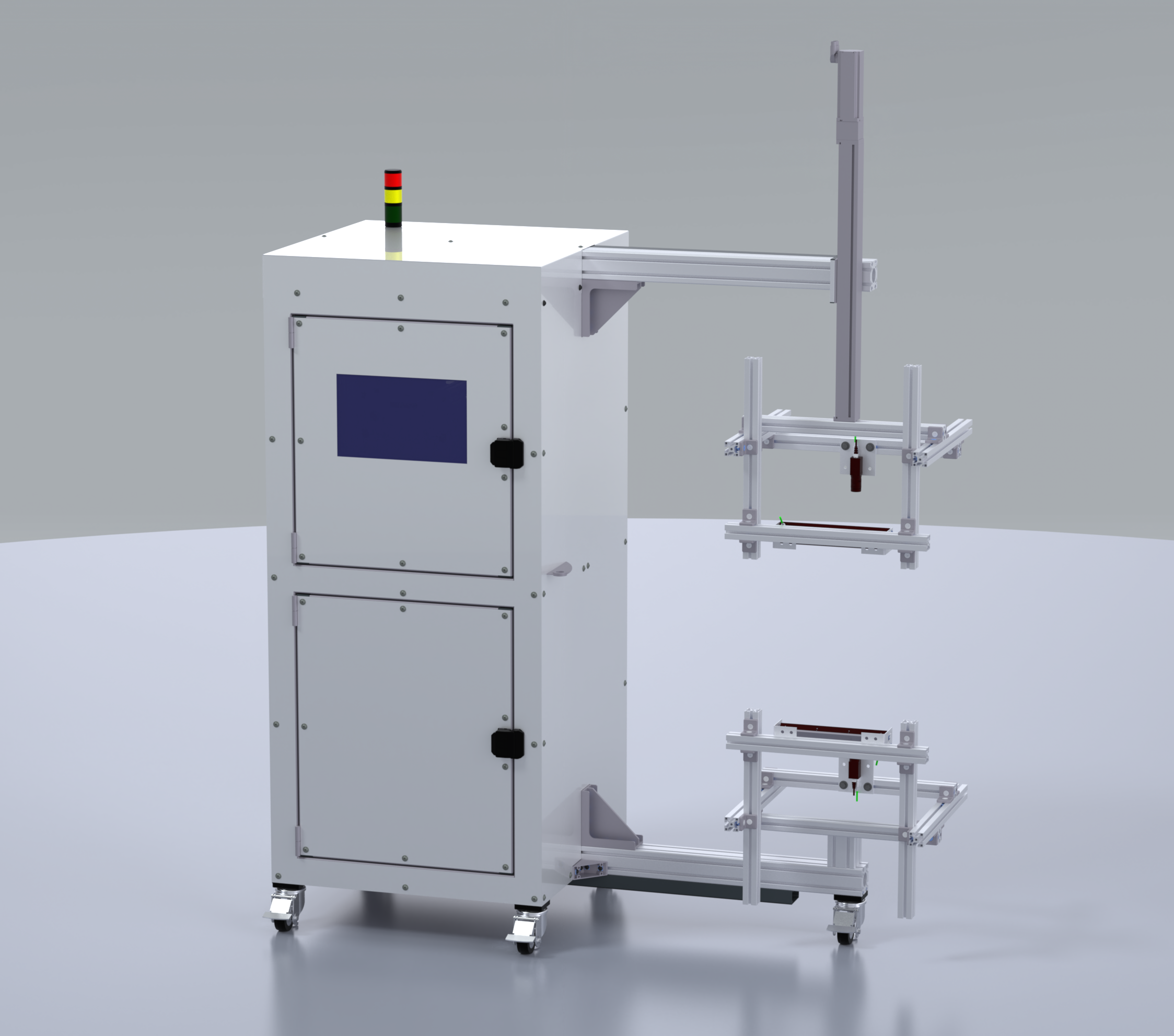

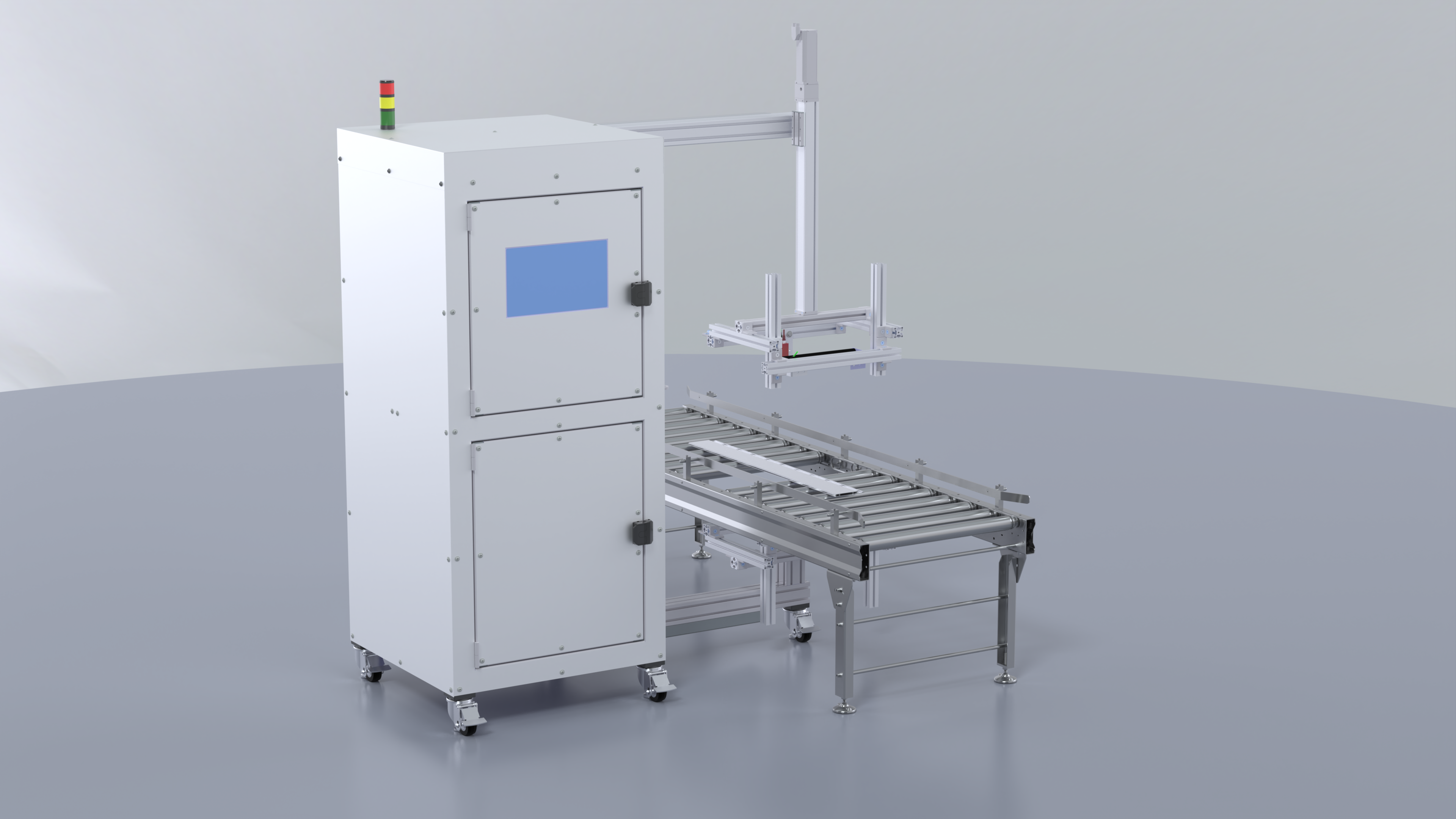

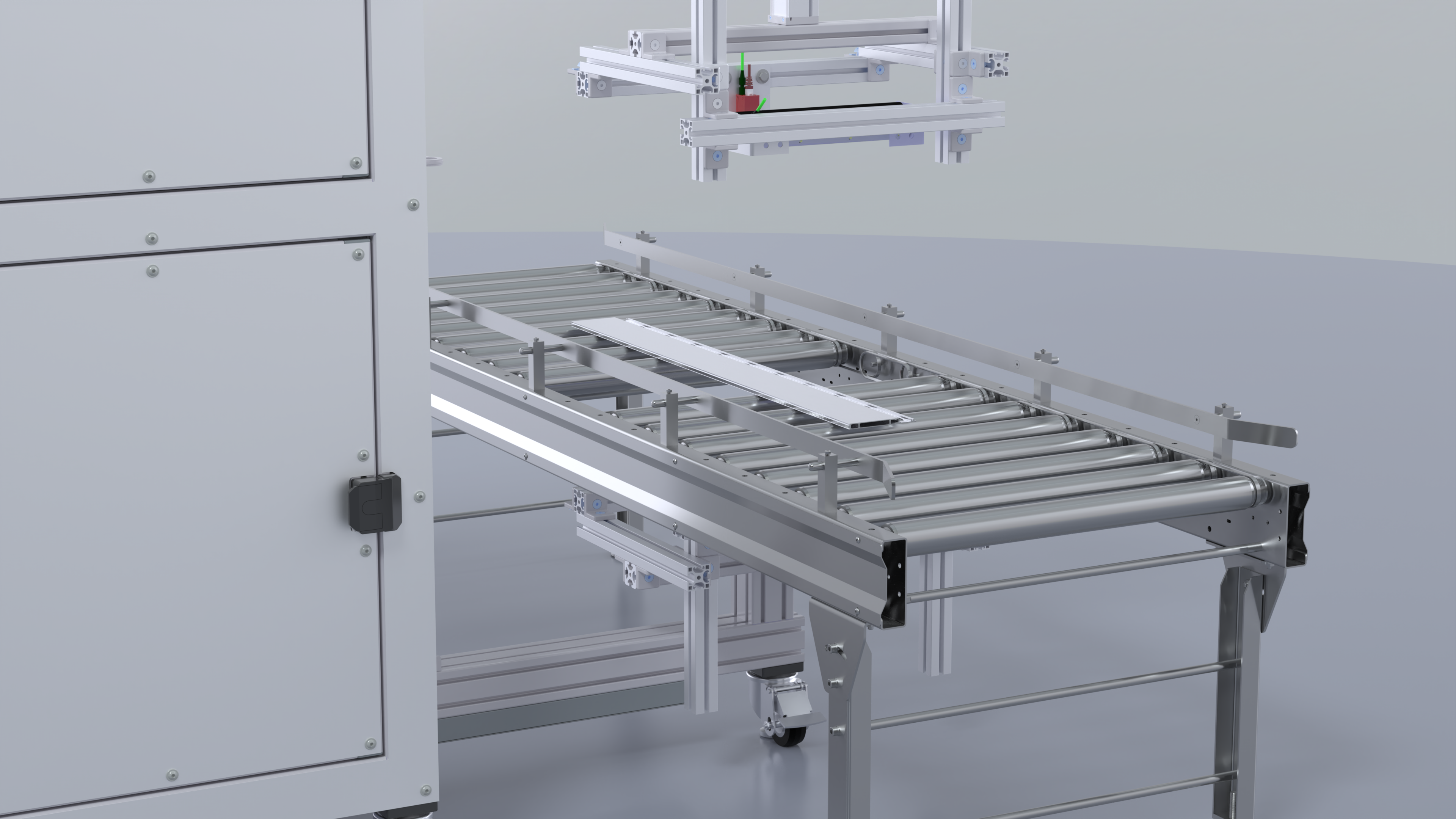

1. CSI-100

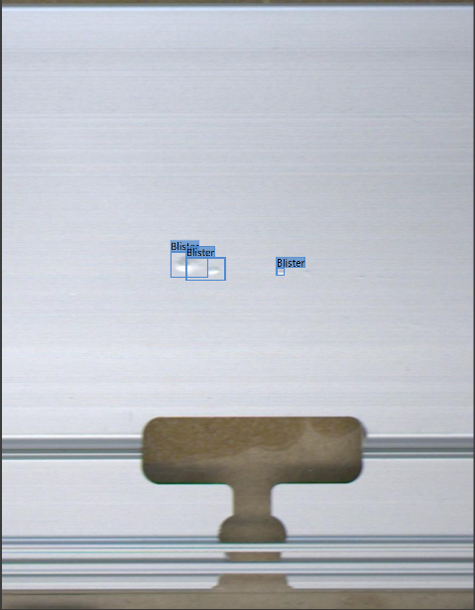

Anomaly detection for extruded products

CSI-100 is a computer-vision system for painted or blank profiles that fits into existing roller/belt conveyors. Combined with Synigen, you generate synthetic data, inject customer-specific anomalies, and deploy robust detection — fast.

Plug into your line

Install CSI-100 without extra line changes. High-accuracy inspection for blank and colored parts, with options like automatic defect marking, new-defect extensions, reporting and analytics.

Top & bottom defects, live signals

Detect top and bottom defects, read QR codes, and ID profile types at line start. Adaptive field-of-view, stack-light operator alerts, and easy PLC / MES / ERP connectivity for reporting and audit trail.

Some of the defects we detect

Scratches

Blisters

Dents

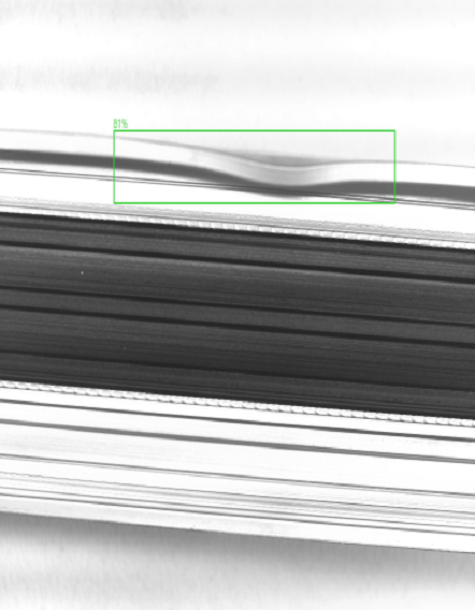

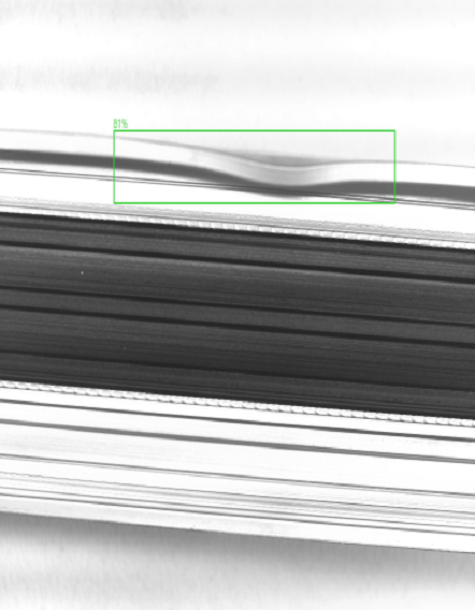

2. LPS

Pressure lines, shape inconsistencies on blanc extruded products

LPS is a laser based solution that allows the detection of pressure lines, shape inconsistencies ... on blanc aluminium parts with high precision. Created with our simulation tool, and with defects injected in the models, the algorithms were validated in real the world application, leading to faster development and deployment.