Synthetic Data

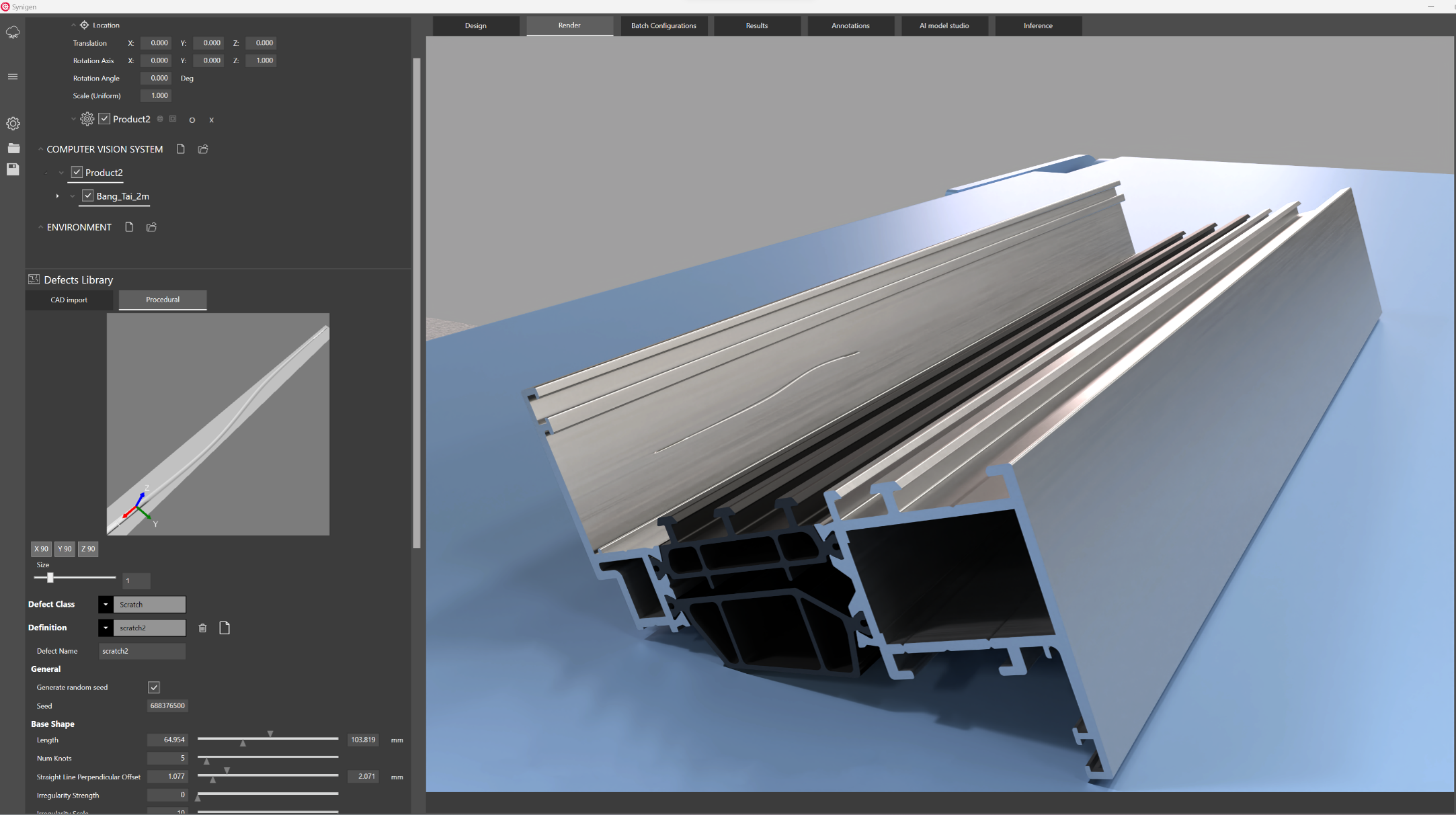

2D/DXF→3D, realistic lighting & optics, defect templates (scratches, dents, folds).

INDUSTRY

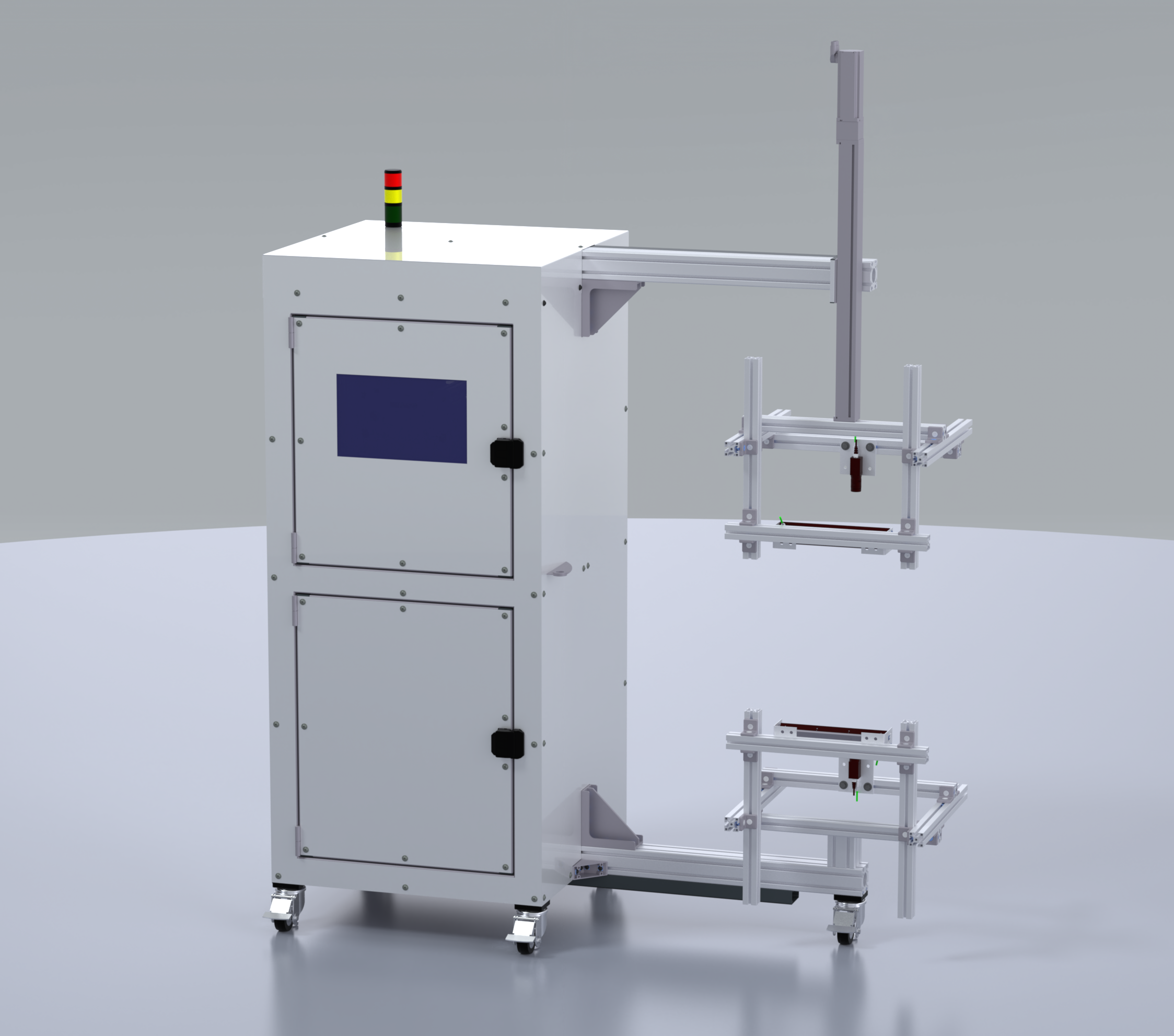

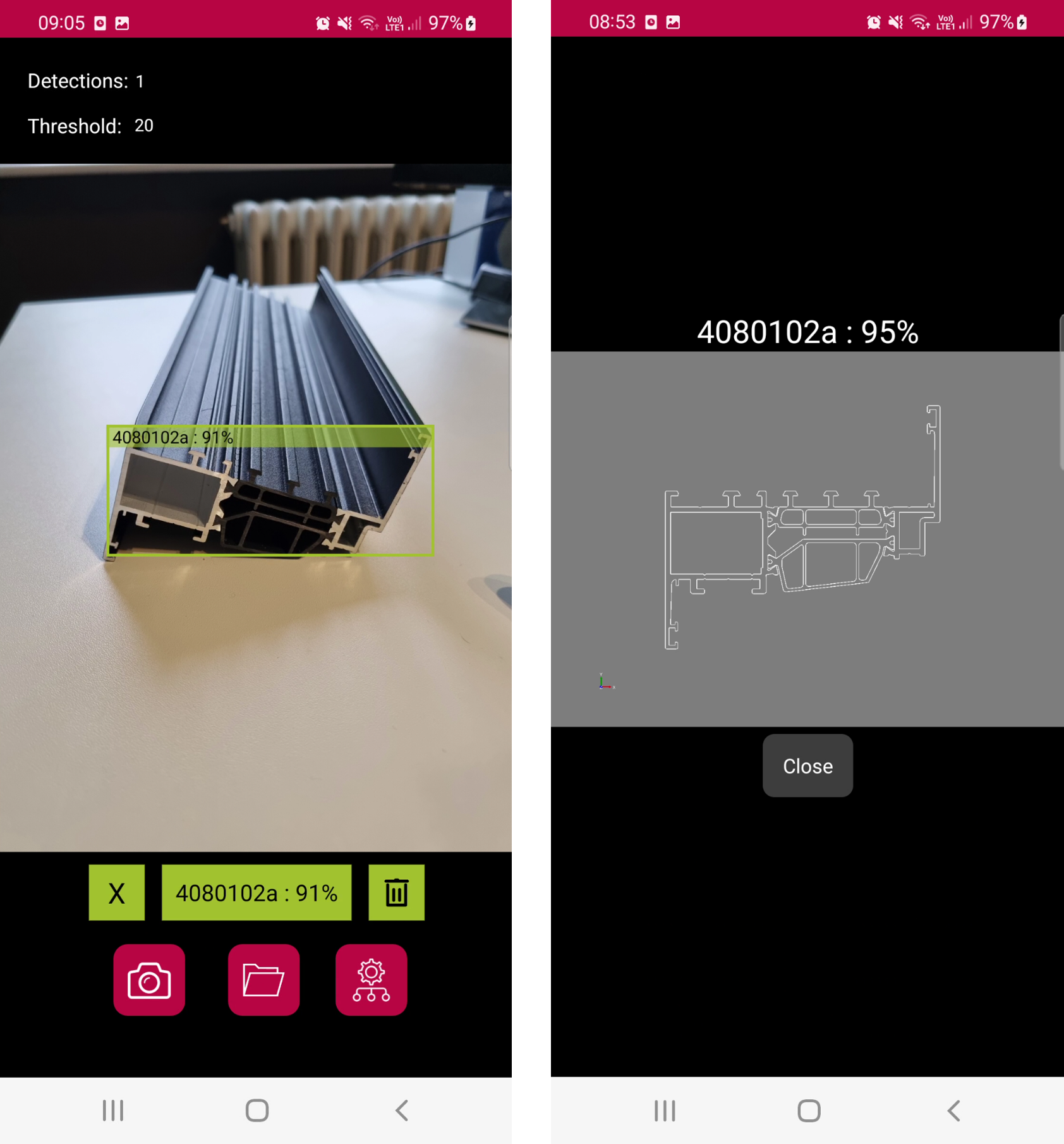

At Curf we help manufacturers integrate AI & machine vision. With Synigen and our CSI-100, you generate synthetic data, detect defects, and accelerate quality — even with no/limited/sparse datasets.

Build robust models with Synigen: 2D/DXF→3D, photorealistic lighting & optics, and configurable defects (scratches, dents, folds). Integrates with your MES/ERP and runs on CSI-100.

Tooling that plugs into existing lines and data flows.

2D/DXF→3D, realistic lighting & optics, defect templates (scratches, dents, folds).

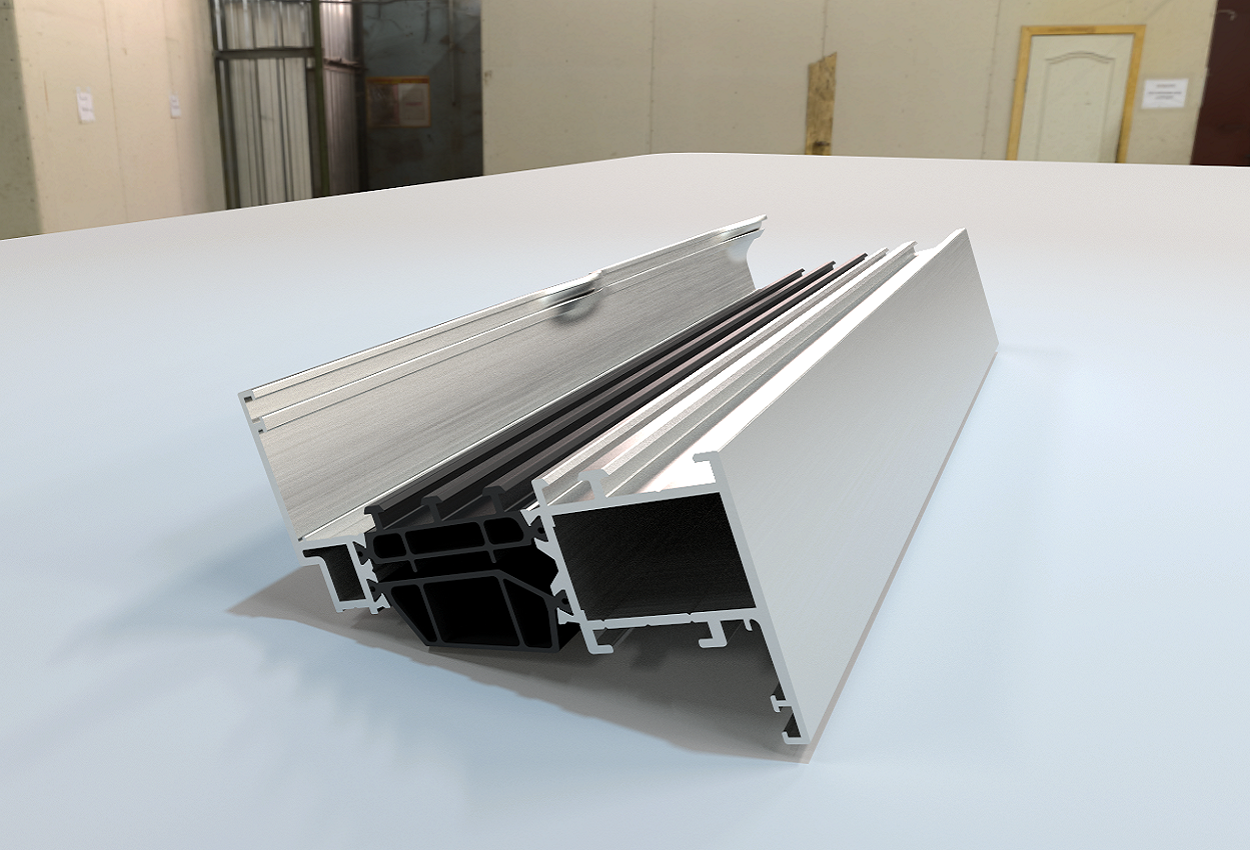

Inline defect detection and type recognition for profiles and parts.

Runs on CSI-100, connects to PLC/MES/ERP, exports KPIs and audit trails.

Faster iterations, less rework, measurable quality improvements.

Our expertise

We are a high-tech engineering team reducing quality cost with AI & machine vision — powered by realistic synthetic data from Synigen. We define and implement the roadmap to your successful AI story.

About